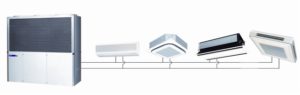

Direct expansion Dx is a dedicated way by the manufacturer for suplying AISIN indoor units.

The outdoor unit controls the operation of compressors and electronic expansion valves of indoor units to reach a preset temperature parameters. This system called VRF differs details of each manufacturer. Power design rules Dx with AISIN GHP show below:

1.Dimensions in piping.

Max-height. between outdoor unit and indoor unit: H ≤50 m by setting it on the roof or H≤ 40 m when set at ground level.

Max-height. between indoor units: h≤ 15 m.

-distance Max. from the first branch to the farthest internal devices: L≤ 60 m.

-Total refrigerant length of piping: up to 520 m.

2.Designing oversizing of installed capacity, number indoor units.

-200% Of the nominal power of GHP, up to 63 indoor units in cooling mode.

-130% Of the nominal power of GHP, up to 41 indoor units in heating mode in our climate.

-in KOMBO installations (two units with one piping GHP) can be installed up to 63 indoor units for heating.

3.Branching refrigerant line to the indoor units.

For this purpose, we have a factory branches and collectors (eight outputs) at the appropriate intervals produced power. At the same rule: the branch can be placed next branch or collector, the collector only the next collector.

4.Types of indoor units.

Possible applications are all indoor units which AISIN production capacities from 2.2 to 28 kW, and the factory sets to control the air exchangers in air handling units (AHU KIT). Exchangers in air handling units can be combined with other peaceful indoor units within the constraints of Section 2. to the outdoor unit (it is possible to connect more than one AHU KIT for GHP). If they exceed the capacity of the ventilation heat exchangers produced the largest capacity model, the design multisection exchangers, with sections of power, eg. After 141 kW. In this way, the number of sections in the heat exchanger and the power is not upper limits. Eliminated is the problem of model E1 to remain GHP in the “thermo off” in achieving the desired temperature. Exchangers take control of air handling units, as AKU KIT Automatic is adapted to the currently used standards.

5.Planning pipe diameter of liquid and gas phase refrigerant R410A.

The principle is that the current diameters are consistent with the stub factory internal and external devices. In some cases (COMBO set of two GHP, exceeding the recommended distance, etc.). There are differences. Therefore, the designer should sent to the technical department Atmopomiar Sp. o.o dimensioned drawing of the proposed installation of devices to convert the chosen and correctly select diameters. The overview will provide in the form of drawings: R410A refrigerant piping sized, statement branches and collectors, the amount of coolant needed to be completed before starting the installation, schedule control cables to the devices and drivers. Designer get here, the data for the design of heat exchangers in ventilation systems freon.